Alizn Professional Customization

Dip Pogo Pin

Spring Loaded Dip Pin Catalog

Dip pogo pin, also known as spring loaded dip pins, dip spring contacts, or through hole spring loaded pins, are primarily used to establish reliable electrical or signal connections between components. They ensure consistent conductivity and stable contact performance in various electronic applications.

Dip Pogo Pins Overview

Dip Pogopin Product Details

With advanced technology and expert craftsmanship, we create durable, high performance custom dip pogo pin / dip spring connector pin tailored to each project’s needs.

What is a dip pogo pin

Dip pogo pins are also called spring pins, pogo pin connectors, and through hole mount spring loaded pins. Their core function is to connect conductive or signal conductors.

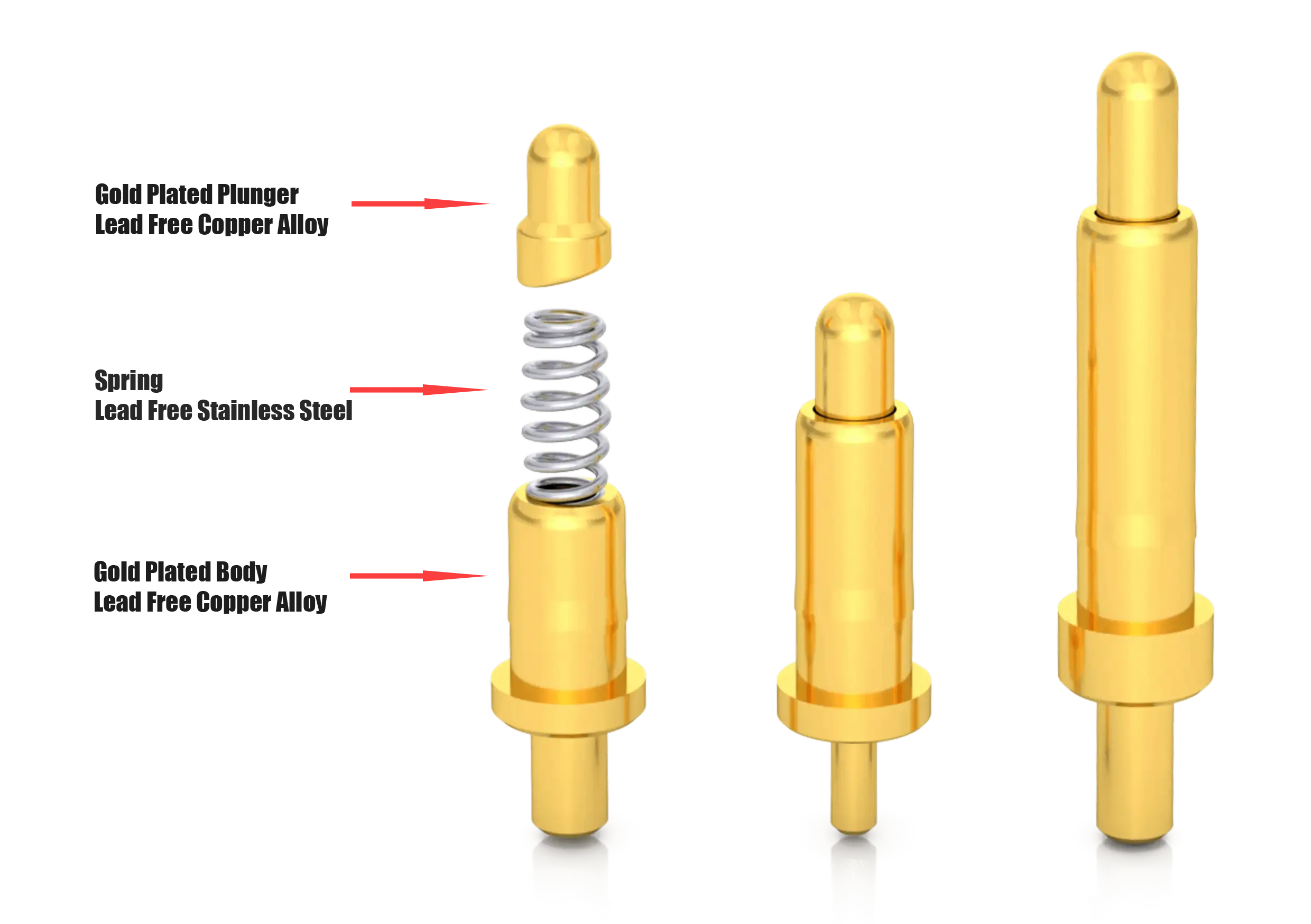

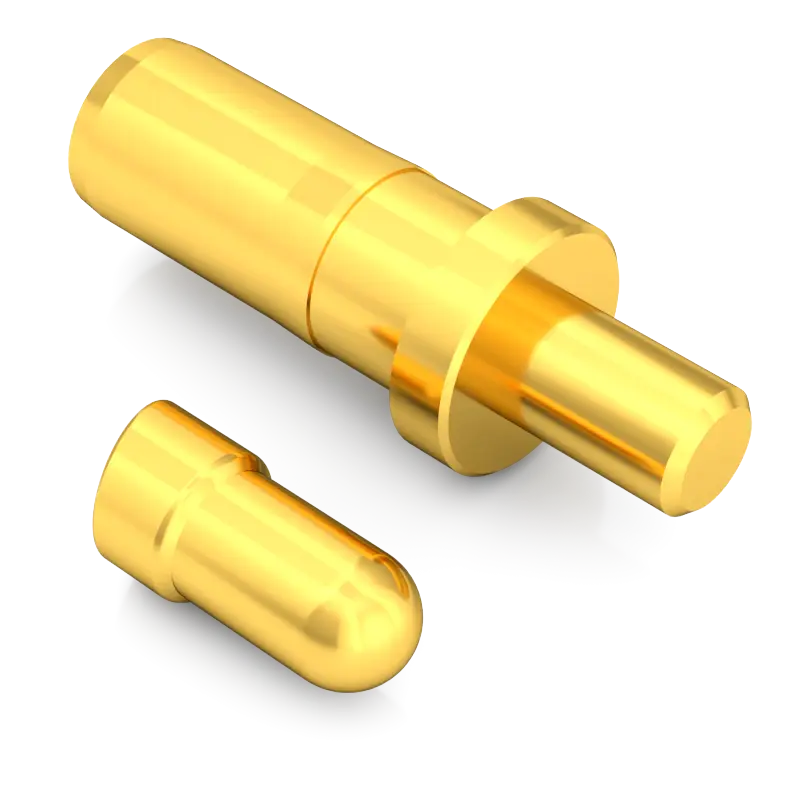

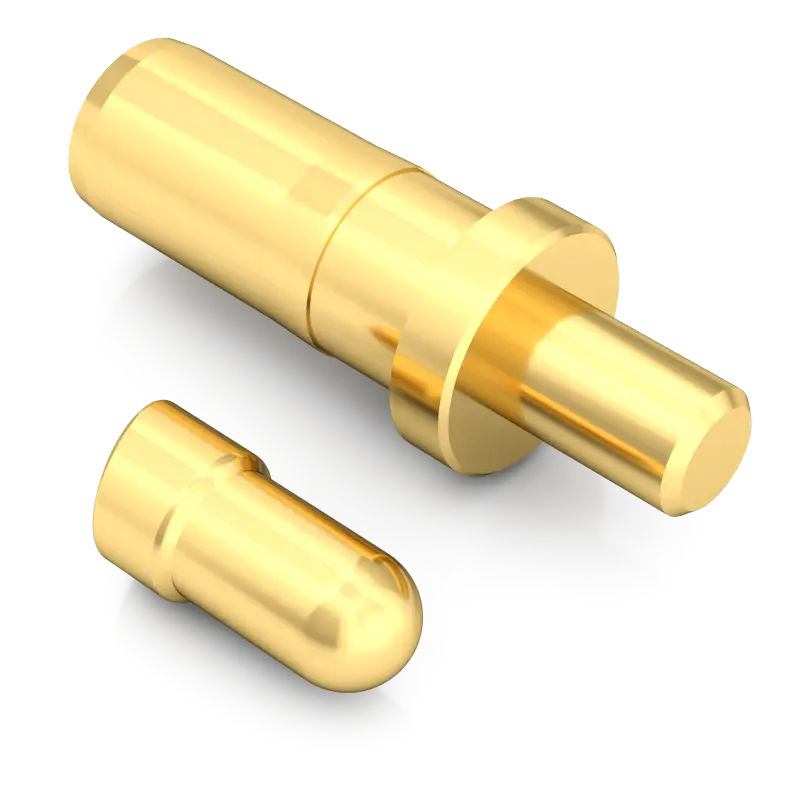

Dip pogo pins are designed with a bevel structure and built in spring mechanism. They are mainly composed of three core components: plunger, spring and body, and are assembled through precision molds and special equipment.

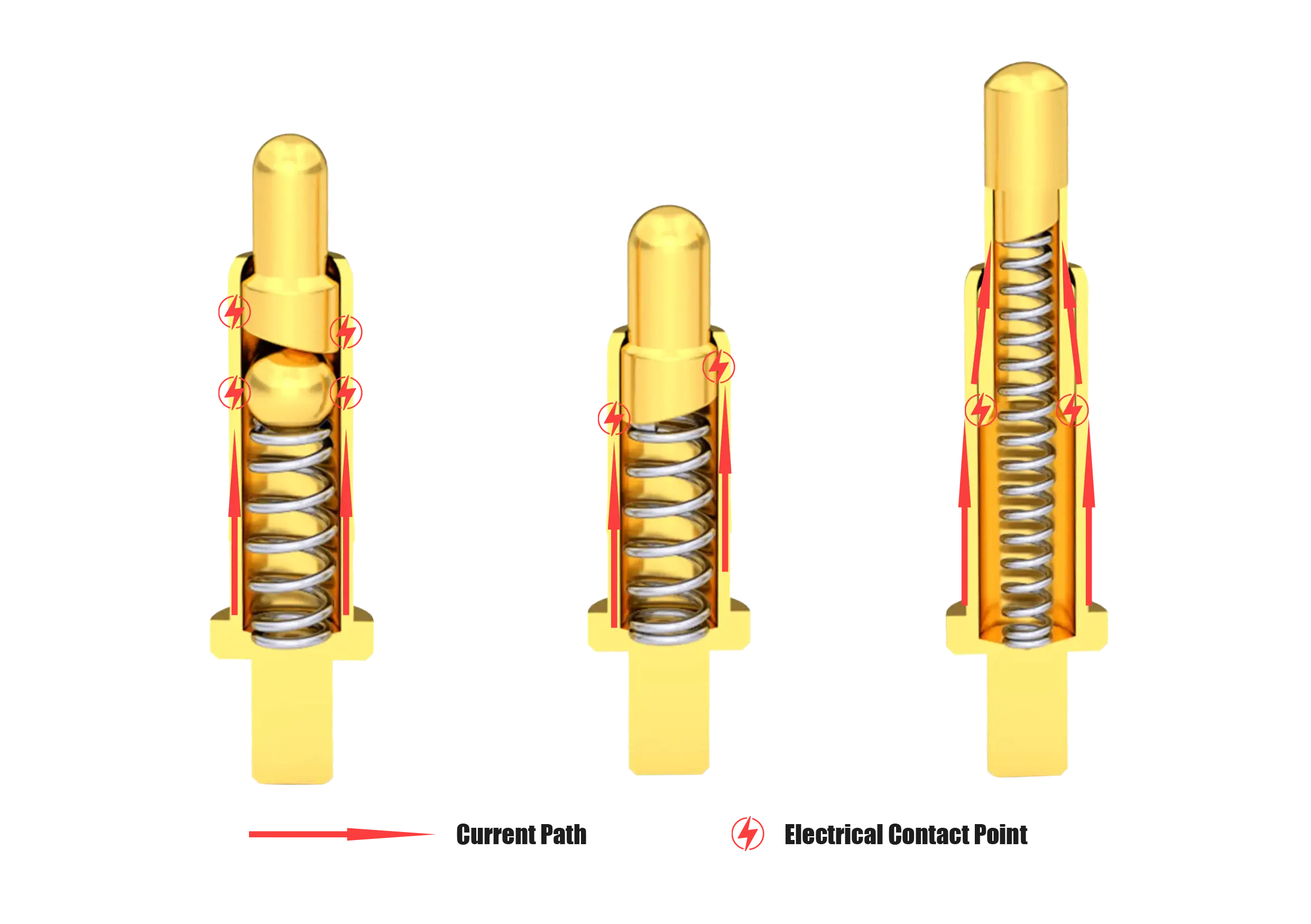

The function of the bevel structure design is to ensure that when the pogo pins are working, the lateral force generated by the contact between the bevel and the spring is used to maintain a stable contact force between the needle and the inner wall of the needle tube, prompting the current path to mainly pass through the gold plated needle (plunger) and needle tube ( body), resulting in stable and extremely low contact resistance, maintaining a stable and reliable connection even during frequent plugging and unplugging.

How to install dip pogo pin

Automatic SMT Reflow Soldering Process: The automatic SMT placement machine positions the dip pogo pins onto the PCB where solder paste has already been printed. The solder tails are precisely aligned and inserted into the plated through-holes, and the assembly then passes through the reflow oven. During reflow, the solder paste melts, wets, and solidifies, forming a firm and reliable bond between the pogo pin and the PCB pads. This method features high automation, excellent accuracy, stable solder joints, and high production efficiency, making it especially suitable for large scale, high consistency manufacturing.

Plug in machine + wave soldering technology: The automatic plug in machine automatically mounts dip pogo pins and accurately inserts the solder pins into the pcb circuit board with printed solder paste, and then melts and fixes the solder paste through the wave soldering process to complete the soldering process with the pcb pad fixed connection. The process is fast, accurate and highly automated, greatly improving production efficiency and product quality. Suitable for electronic components with extremely long solder legs that cannot be fixed through SMD reflow soldering.

Dip pogopin material & Parts

DIP pogo pins belong to the pogo pin connector family and are spring loaded contact components developed based on a precision angled internal spring structure. Each pin typically consists of three key elements: the plunger, the spring, and the barrel.

This type of pogo pin features integrated soldering legs, ensuring accurate positioning and strong mechanical bonding with the PCB. It provides low contact resistance, stable electrical performance, reliable long term durability, and high soldering strength when assembled onto circuit boards. As a result, DIP pogo pins deliver stable connections and extended service life, making them suitable for applications requiring repeated contact and signal transmission.

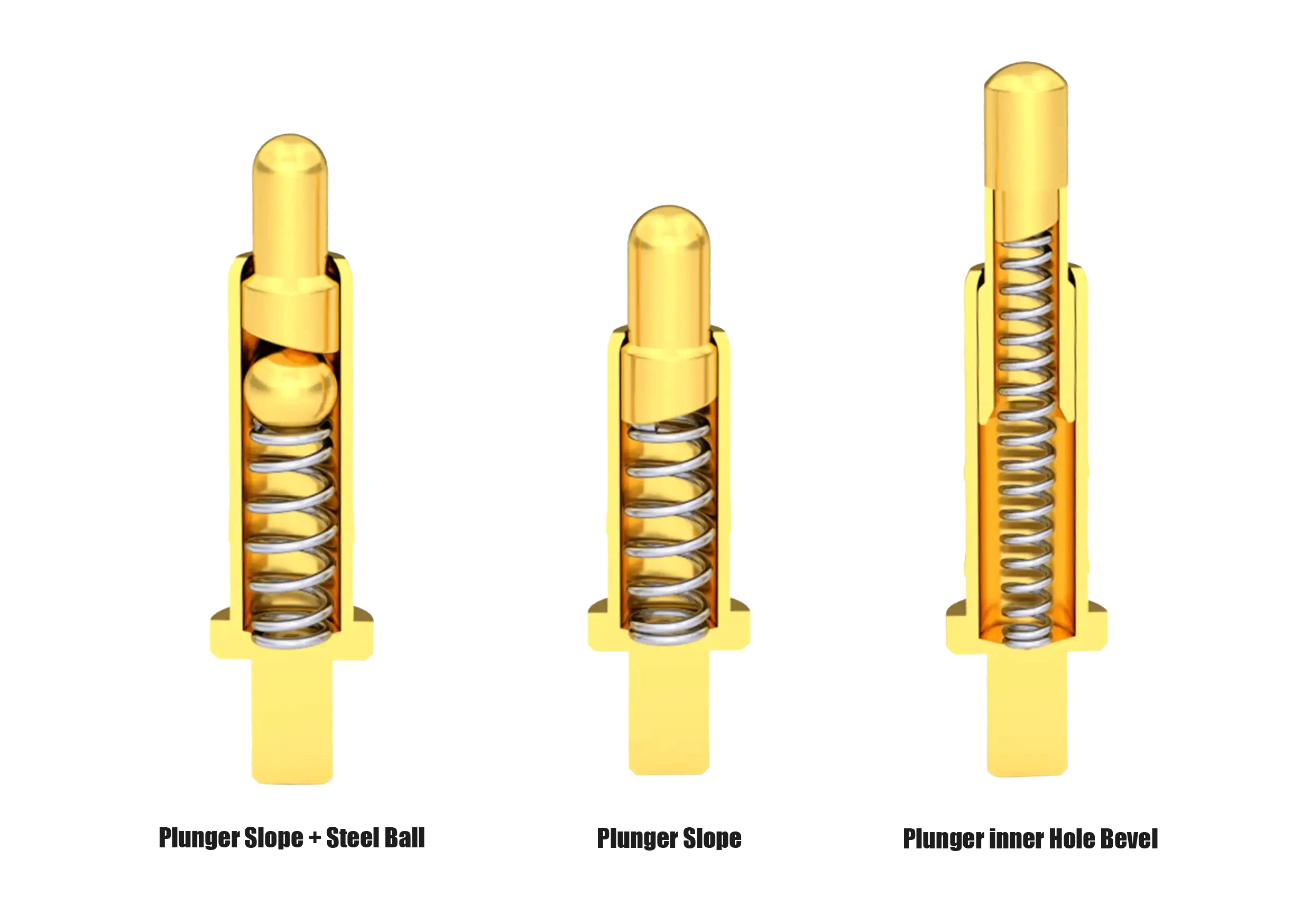

Dip pogopin Internal Structures

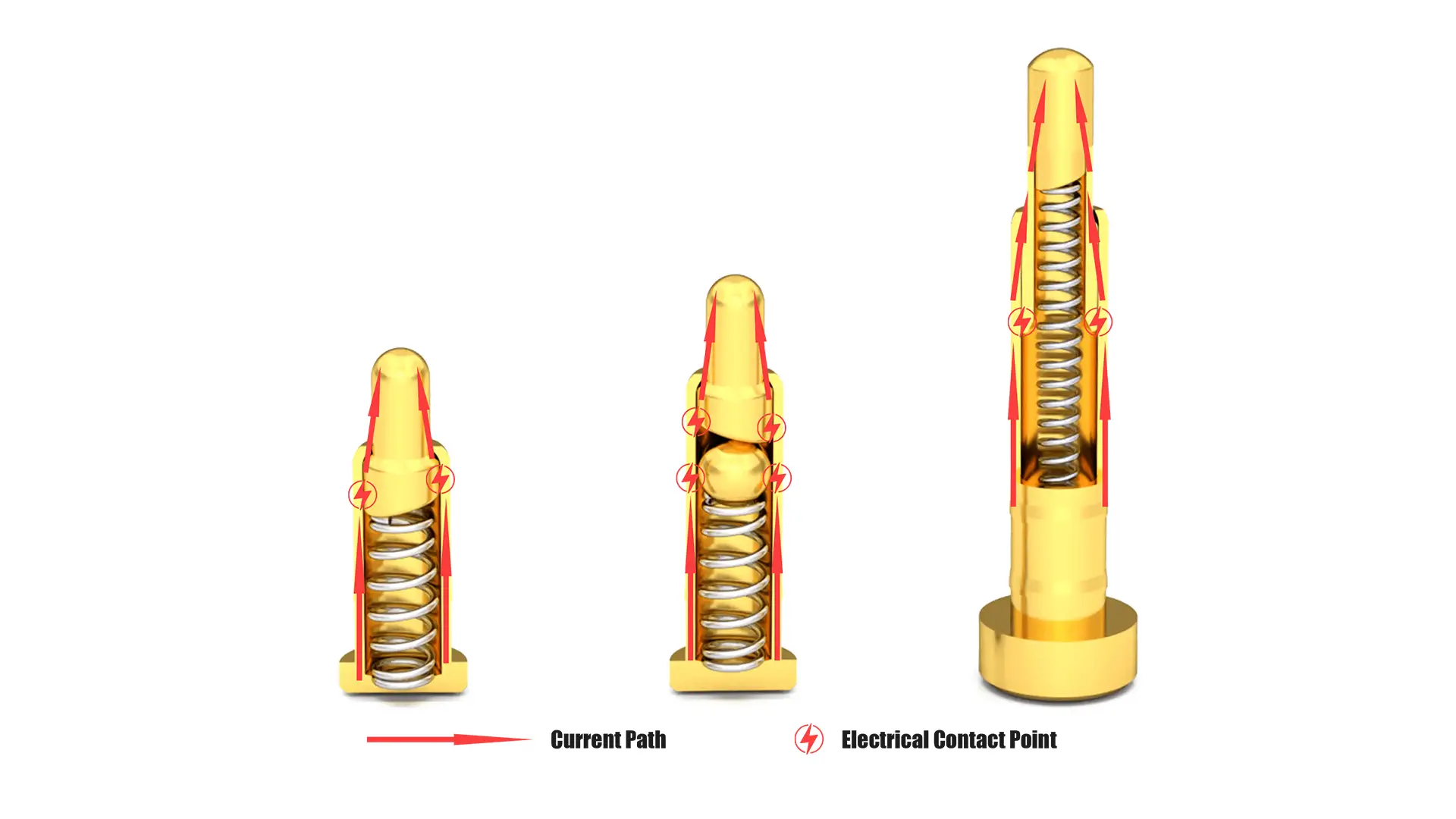

There are three commonly used internal structures of Alizn dip pogo pins, namely Plunger bevel structure, Plunger bevel + steel ball structure and Plunger inner hole bevel structure.

How DIP Pogo Pins Work

Contact force and contact resistance are the key factors that determine the stability and reliability of an electrical connection. These two parameters are directly related: increasing the contact force helps reduce contact resistance. Therefore, maintaining a stable contact force is essential to achieving low and consistent contact resistance.

In a dip pogo pin, the internal spring and beveled structural design generate a lateral force during compression. This force ensures that the gold plated plunger remains in constant, stable contact with the inner wall of the barrel. As a result, the pogo pin achieves a consistently low contact resistance and ensures a dependable and repeatable electrical connection.

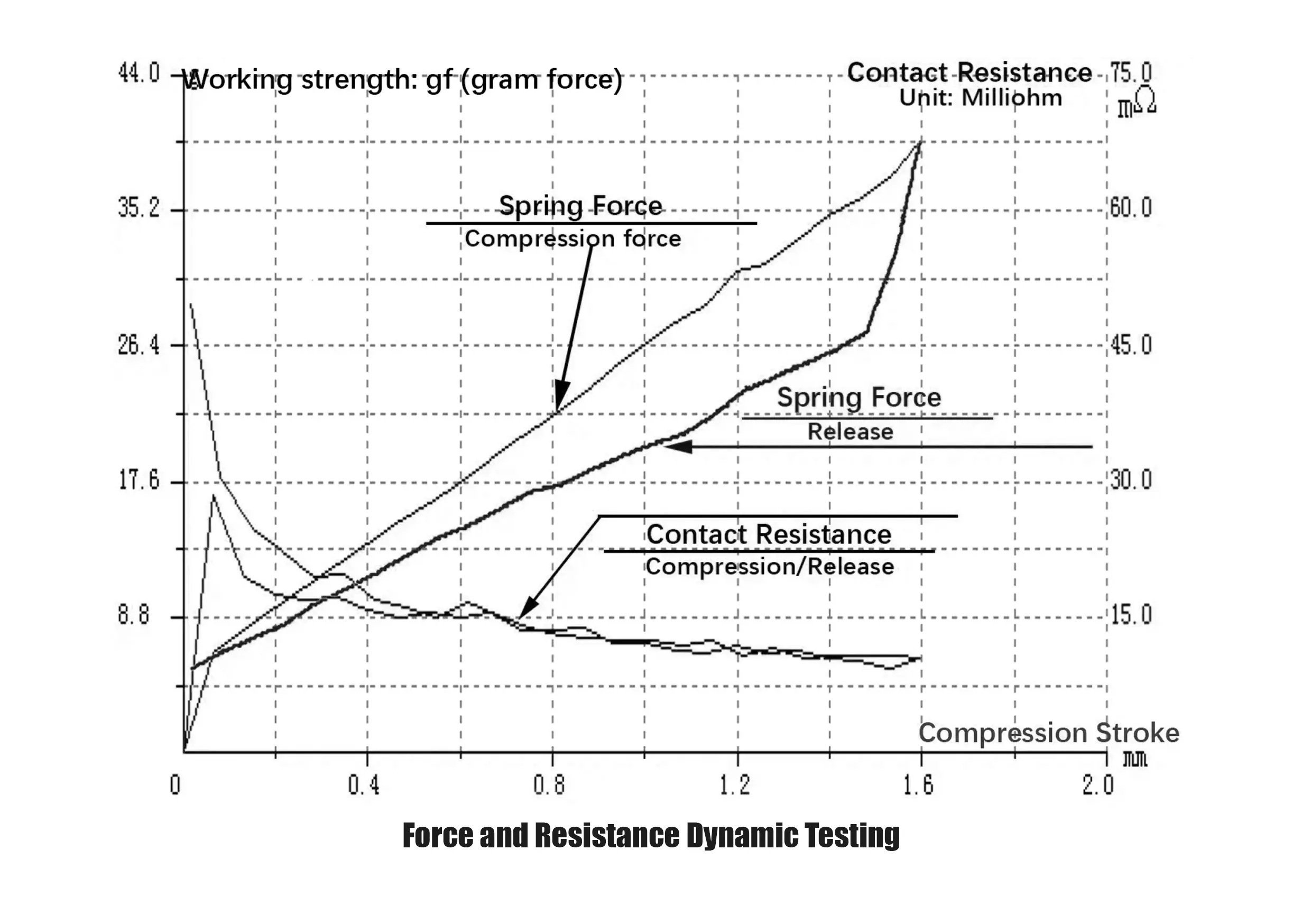

Dip Pogo Pin Contact Resistance

This chart illustrates that during the full compression and release stroke of the dip pogo pin, the spring force increases smoothly while the contact resistance remains extremely low and stable. This demonstrates a well engineered internal structure, precise machining tolerances, and high quality vacuum blind hole plating that together ensure reliable electrical connectivity and long term performance stability.

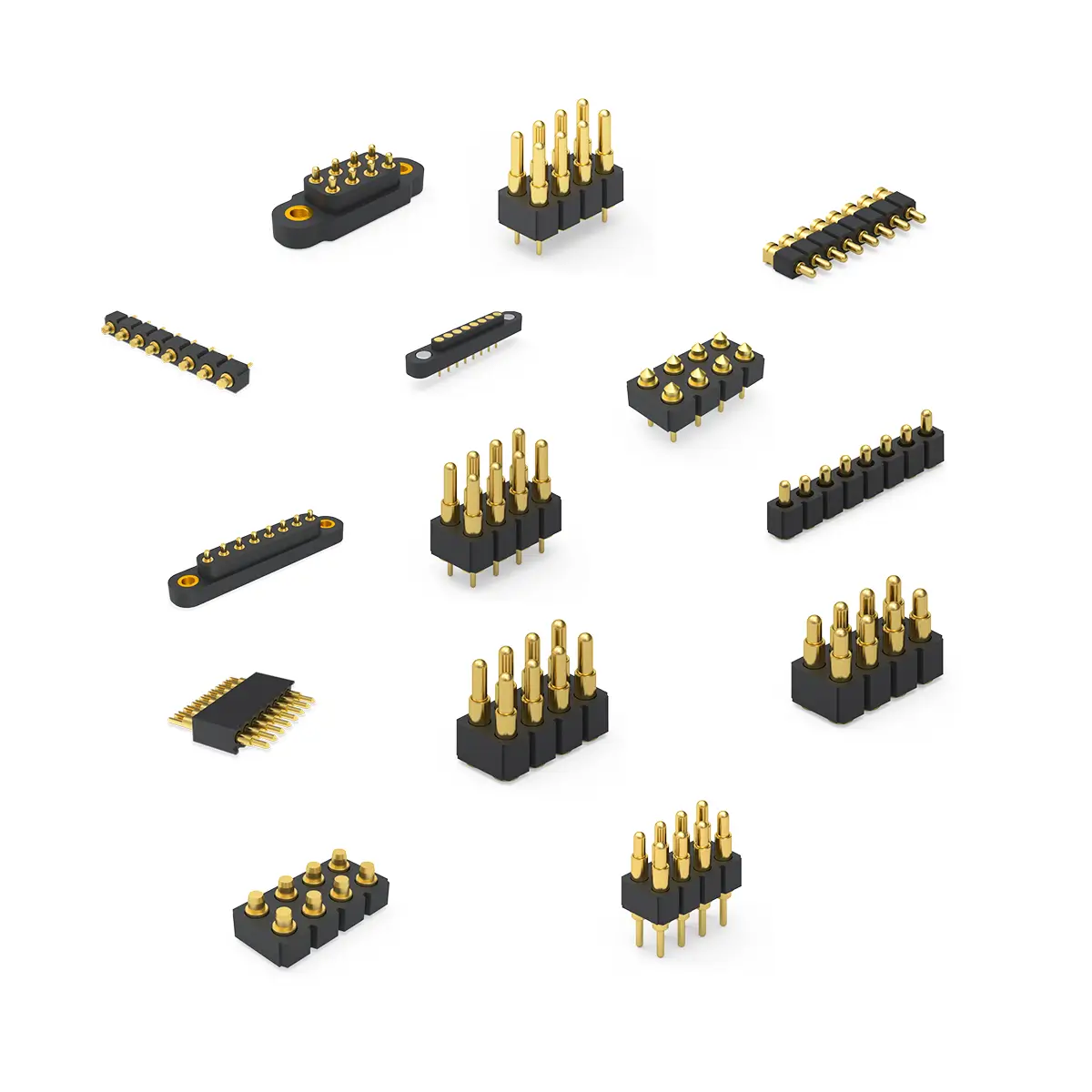

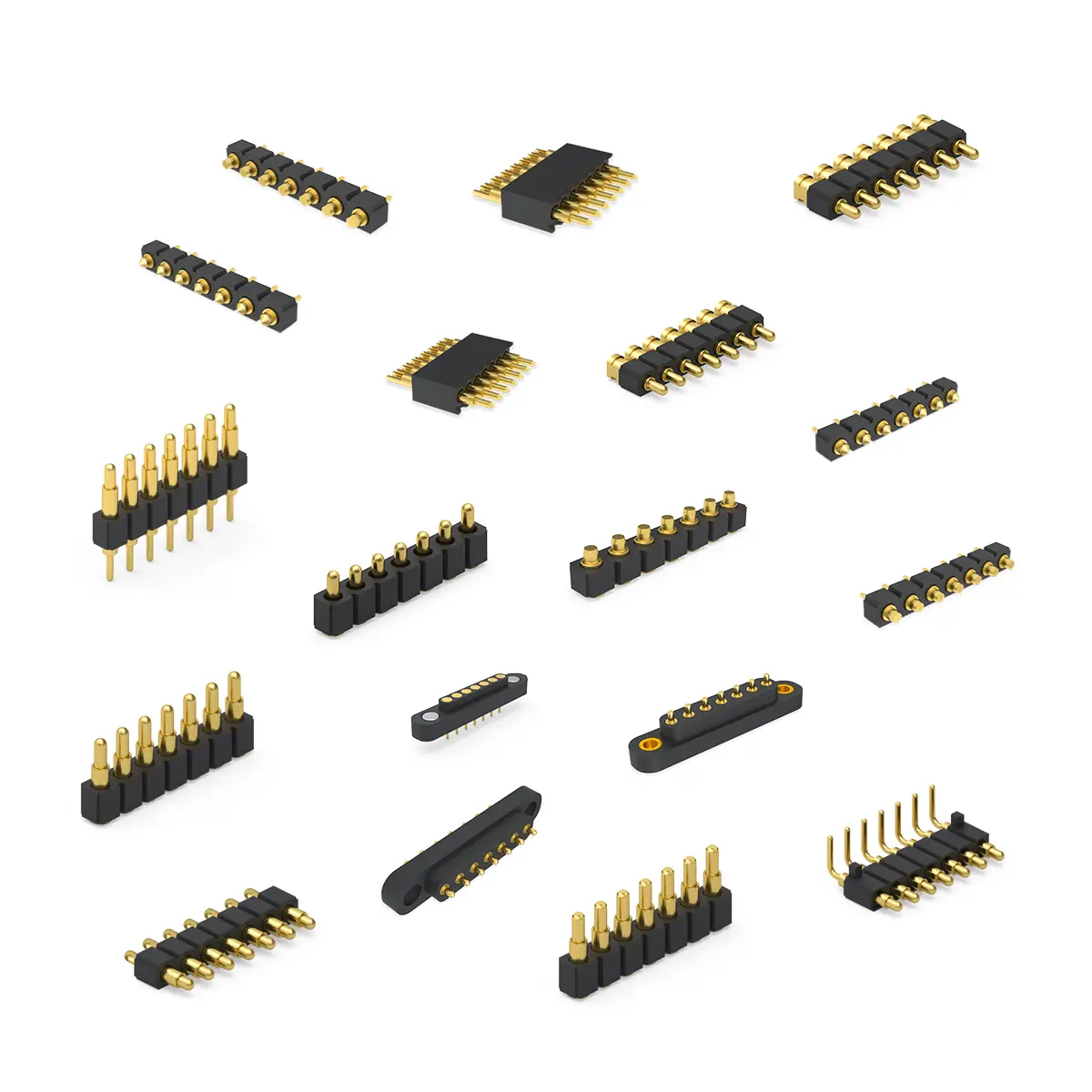

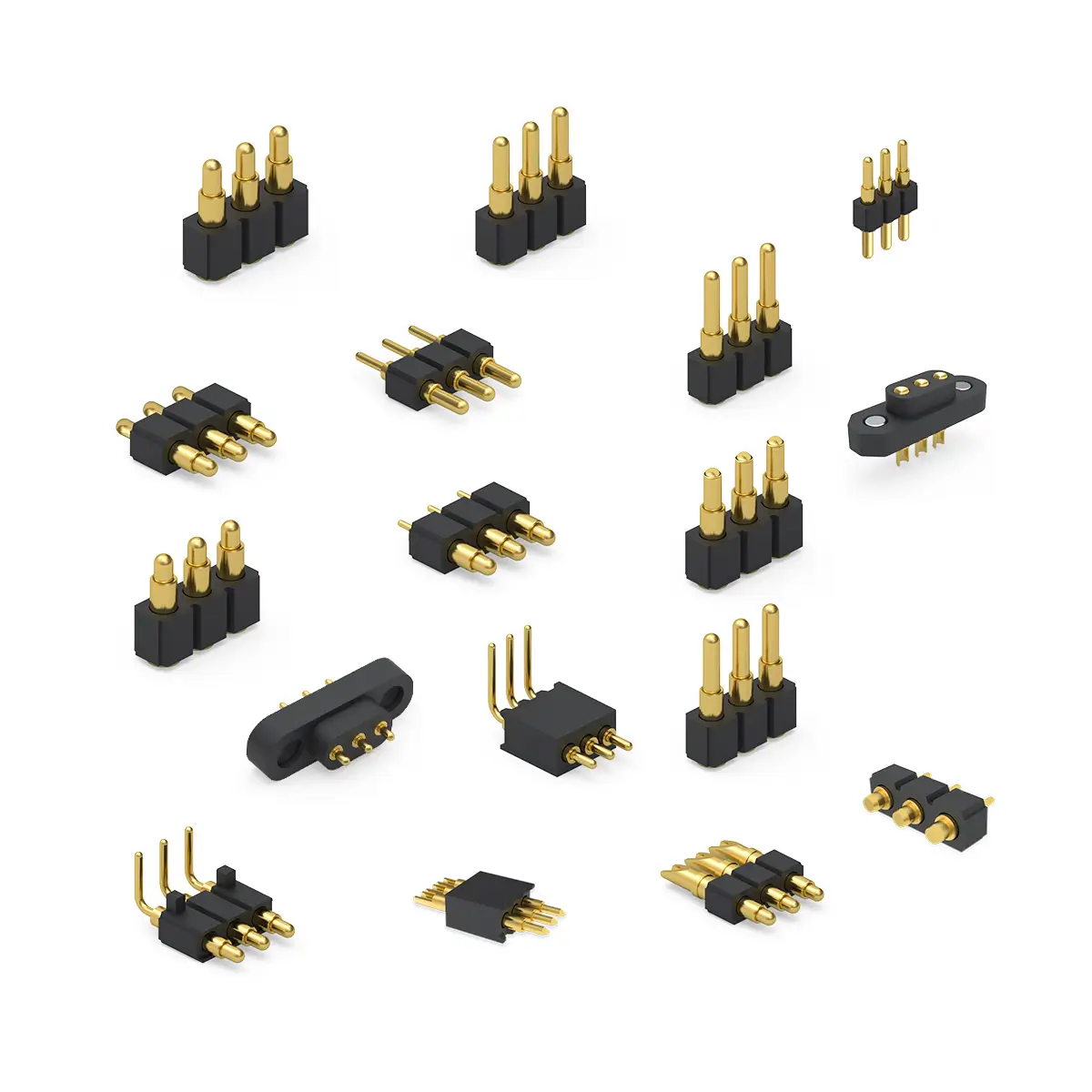

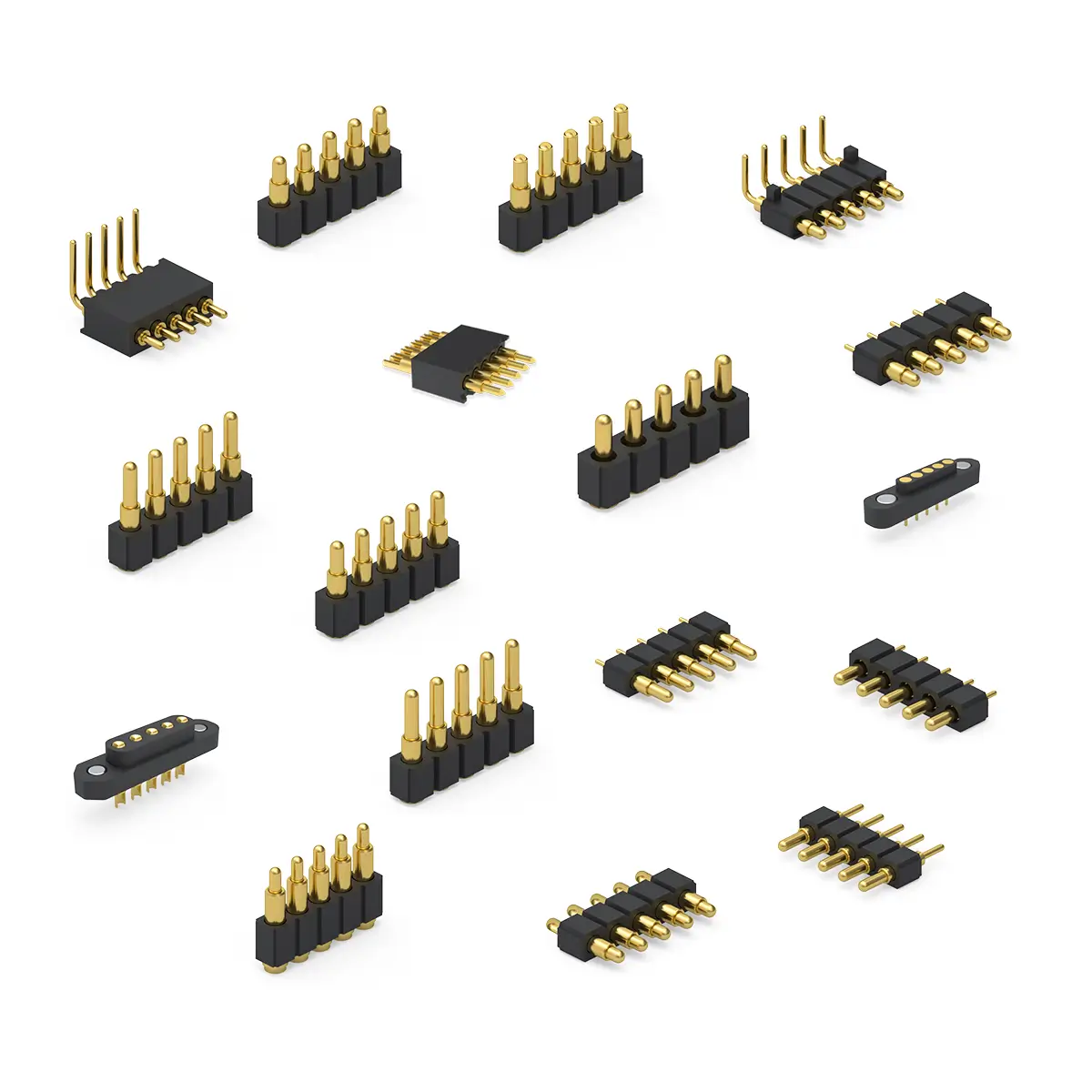

types of spring loaded dip pin

Selection Guide of Dip Pogo Pin

Fully customizable to meet any electrical, mechanical, or environmental requirements.

| SN | Product Image | Full Stroke (mm) | Initial Height (mm) | Working Height (mm) | Catalog Download |

|---|---|---|---|---|---|

| 1 |  |

0.4~0.8 | 1.80~3.00 | 1.40~2.60 | Short-Dip Pogo Pins |

| 2 |  |

1.00 | 3.15~6.30 | 1.50~5.60 | 1.00-Dip Pogo Pins |

| 3 |  |

1.50 | 4.50~10.00 | 3.20~9.00 | 1.50-Dip Pogo Pins |

| 4 |  |

2.00 | 5.80~16.00 | 4.00~15.00 | 2.00-Dip Pogo Pins |

| 5 |  |

2.50 | 7.10~16.00 | 4.80~15.00 | 2.50-Dip Pogo Pins |

| 6 |  |

3.00 | 8.40~20.00 | 5.60~19.00 | 3.00-Dip Pogo Pins |

| 7 |  |

3.50~5.00 | 9.70~20.00 | 6.40~19.00 | 5.00-Dip Pogo Pins |

Dip Spring Loaded Pin Performance

Dip Pogo Pin Technical Parameters

Alizn custom pogo pins are carefully crafted using only the finest materials.

Our production team offers superior craftsmanship with over 10 years of experience working with custom dip pogo pins / dip pogo pin connectors.

| Items | Details |

|---|---|

| Material | Plunger: Lead-Free Copper Alloy |

| Body: Lead-Free Copper Alloy | |

| Spring: Stainless Steel | |

| Solid Pin: Lead-Free Copper Alloy | |

| Main Technical Parameters | Standard state: |

| Operating temperature: -40~+120°C (Standard) | |

| Operating humidity: 20-85% RH | |

| Storage temperature: -10~+50°C | |

| Storage humidity: 20-85% RH | |

| Rating voltage: 36V AC/DC (Standard) | |

| Rating current: 2A/Pin Continuous (Standard) | |

| Contact resistance: 30 mΩ Max. (Standard) | |

| Withstanding voltage: 250V AC, 1 Minute | |

| Insulation resistance: 500 MΩ Min. | |

| Durability: 10,000 Cycles (Standard) | |

| Working Spring Force: 40~120 gf (Standard) | |

| Electroplating | Plunger: Ni Plating 1.4μm, Gold Plating 0.30μm |

| Body: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| Solid Pin: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| Contact Type | Vertical Contact Type |

| Installation Method | SMT automatic placement machine + Reflow soldering |

| Plugin machine + Wave soldering | |

| Environmental Protection Standard | Comply with EU RoHS and Alizn standards |

Upload Your CAD File

To begin, provide your contact details and upload the CAD file or detailed product requirements of your design. This allows us to create a detailed 3D model of the part or prototype you're looking to produce.

Receive a Quote & Design Review

Within 12 hours, we’ll send you a detailed quote along with Design for Manufacturability (DFM) feedback. This ensures the feasibility of your project and gives you a clear idea of the costs involved.

Confirm Your Order & Begin Production

Once you approve the quote and design, we’ll proceed with the production of your custom dip pogo pins.

Shipping & Delivery

Your project enters our manufacturing queue the morning after we receive your approval. On average, custom orders ship within 10-15 business days. In stock products and samples ship within 48 hours.

Just 4 Steps

Custom Dip Pogo Pin Quotation Process

From detailed consultation to final delivery, we make custom pogo pin orders simple and easy. We pride ourselves on providing exceptional customer service by anticipating your needs, offering customized solutions and on time delivery.

Dip Spring Loaded Pins Electroplating

Dip Pogo Pin Surface Treatment

Various surface treatment methods to meet your needs

Electroplated Gold - Golden Yellow

Electroplated Nickel - Silver White

Before Electroplating - Brass Color

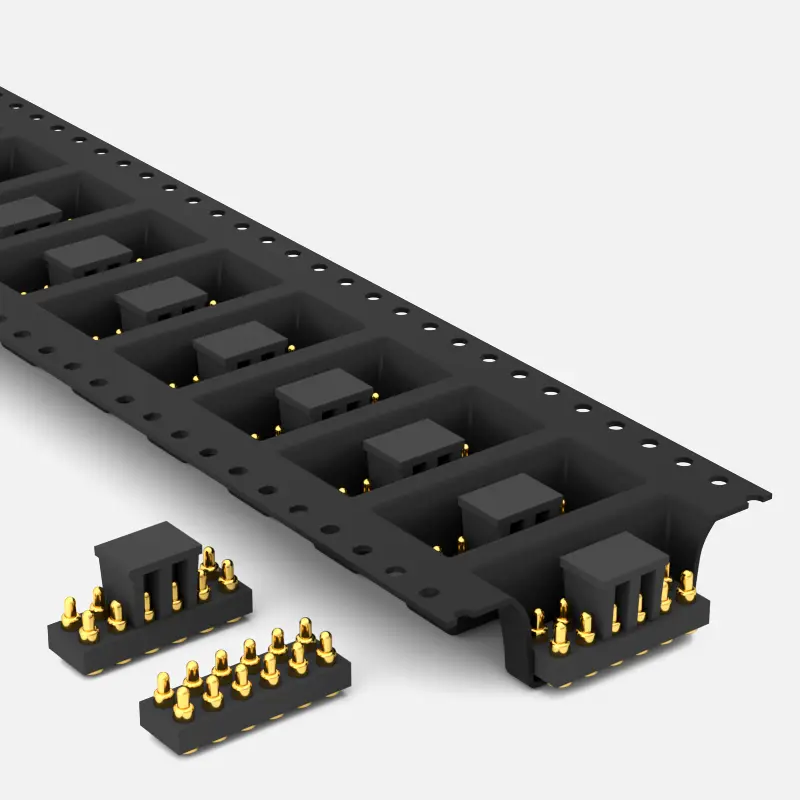

Packaging Options for Dip Pogopin

Pogo Pin Packaging Method

Enabling you to move seamlessly from receiving to production without compromise.

Pogo Pins Vacuum Carrier Tape Packaging

Pogo Pin Connector Vacuum Carrier Tape Packaging

Dip Contact Pin Customization Process

From Design to Quality Control

Every Step Tailored to Perfection

Alizn dip pogo pin customization process ensures precision, quality, and efficiency at every stage. From innovative design and advanced production to rigorous quality control, we transform your ideas into high performance solutions. Serving diverse industries, we specialize in creating prototypes and full scale production, turning your vision into reality with unmatched expertise and attention to detail.

- RX Feugiat 2000

- 4-5 months

- $ 8,400

Professional Equipment For Dip Springloaded Pin

The Equipment Behind Custom Pogo Pins

Our professional equipment provides complete solutions for pogo pin customization, ensuring high precision, efficiency, and cost effectiveness.

From design to production, we meet strict quality standards, addressing complex shapes and performance needs.

automatic lathe

High speed auto feeding turning

milling machine

Complex precision machining

stamping press

High accuracy & rigidity

spring coiling machine

Free height & wire diameter precision

electroplating machine

Uniform, clean

coordinate measuring machine

Dimensional & tolerance verification

Alizn Pogo Pin

Related Pogo Pin

From initial prototypes to large scale production, we ensure top quality results and help you achieve your manufacturing goals.

Pogo Pin Professional Guide

Pogo Pin Knowledge

Alizn explores with you every factor that influences your choice design, functionality, durability, price factors, process, customization options

Dip Pogo Pin FAQ

Alizn high performance pogo pins, ideal for functional tests or end use applications. Explore our FAQs to discover more about our pogo pin solutions and related technical support.

We need drawings or key specs: size, stroke, force, current, plating, and usage.

Standard parts: 3–7 days. Custom parts: 2–4 weeks depending on complexity.

Yes, sample testing can be provided before mass production.

Yes, we can design sealed / IP67–IP68 waterproof structures.

Yes, we support full customization based on size, force, plating, and structure.