Alizn Professional Customization

Right Angle Pogo Pin

Spring Loaded Dip Pin Catalog

Right angle pogo pin, also known as spring loaded right angle pins, right angle spring contacts, or through hole spring loaded right angle pins, are primarily used to establish reliable electrical or signal connections between components. They ensure consistent conductivity and stable contact performance in various electronic applications.

Right Angle Pogo Pins Overview

Right Angle Pogopin Product Details

With advanced technology and expert craftsmanship, we create durable, high performance custom right angle pogo pin / right angle spring connector pin tailored to each project’s needs.

What is a right angle pogo pin

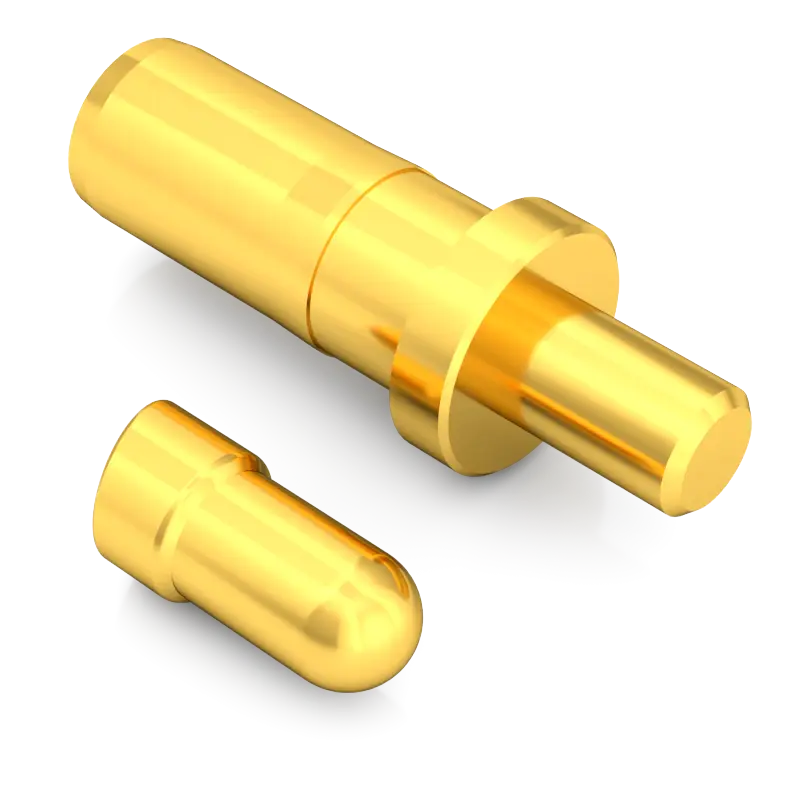

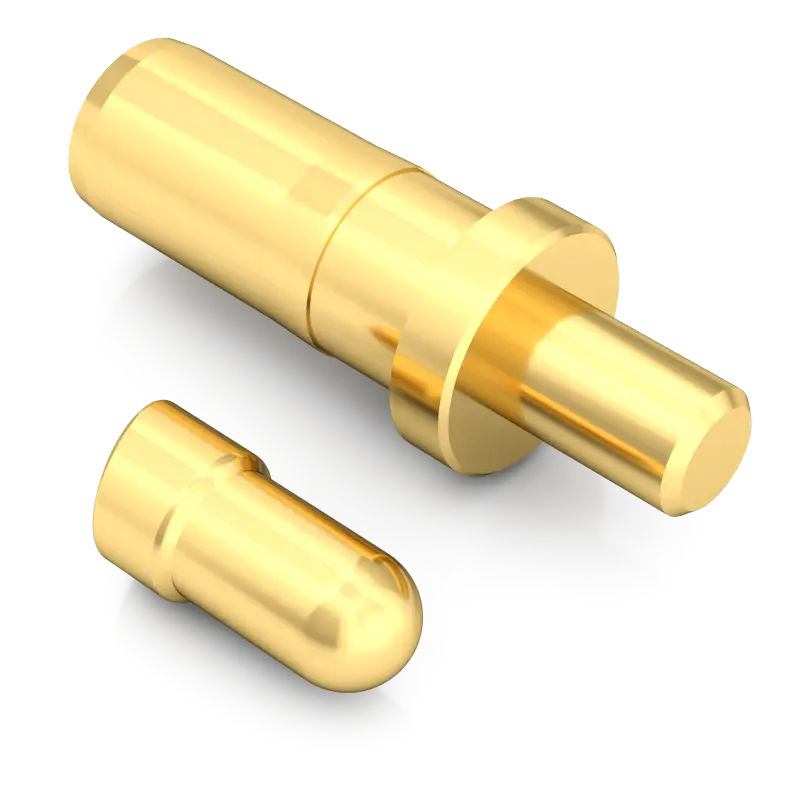

A right angle pogo pin is a type of spring loaded electrical contact designed so that the contact tip and the solder or mounting tail are oriented at 90 degrees to each other. Unlike standard vertical pogo pins, which transfer signals straight through the pin body, right angle pogo pins allow signals to be routed horizontally along a printed circuit board (PCB).

Structurally, it consists of a plunger, spring, and barrel, similar to a conventional pogo pin, but the internal conductor is bent or engineered to maintain reliable electrical continuity through the right angle path. This design is especially useful in space constrained layouts, where vertical clearance is limited or where side entry connections are required.

Right angle pogo pins are commonly used in test fixtures, board to board connections, docking stations, and compact consumer electronics. They provide temporary yet reliable electrical contact, tolerate misalignment, and support repeated mating cycles. Their main advantages are mechanical flexibility, reduced PCB height, and improved routing options in dense electronic assemblies.

How to install right angle pogo pin

Installing a right angle pogo pin requires careful attention to alignment, mechanical stress, and electrical reliability. Before installation, confirm that the pogo pin specifications, such as pin diameter, stroke length, spring force, and mounting type match the application requirements. Also verify that the PCB or housing hole size, tolerance, and orientation are designed specifically for a right angle configuration.

For press fit right angle pogo pins, use a dedicated jig or press tool to apply uniform force in the correct direction. Avoid tilting during insertion, as this can damage the barrel or deform the internal spring. For solder mount types, position the pogo pin accurately and control soldering temperature and dwell time to prevent heat damage to the spring mechanism.

After installation, inspect the pogo pin to ensure smooth plunger movement, proper contact force, and correct angle alignment. Finally, perform electrical continuity and functional testing to confirm stable and reliable contact performance.

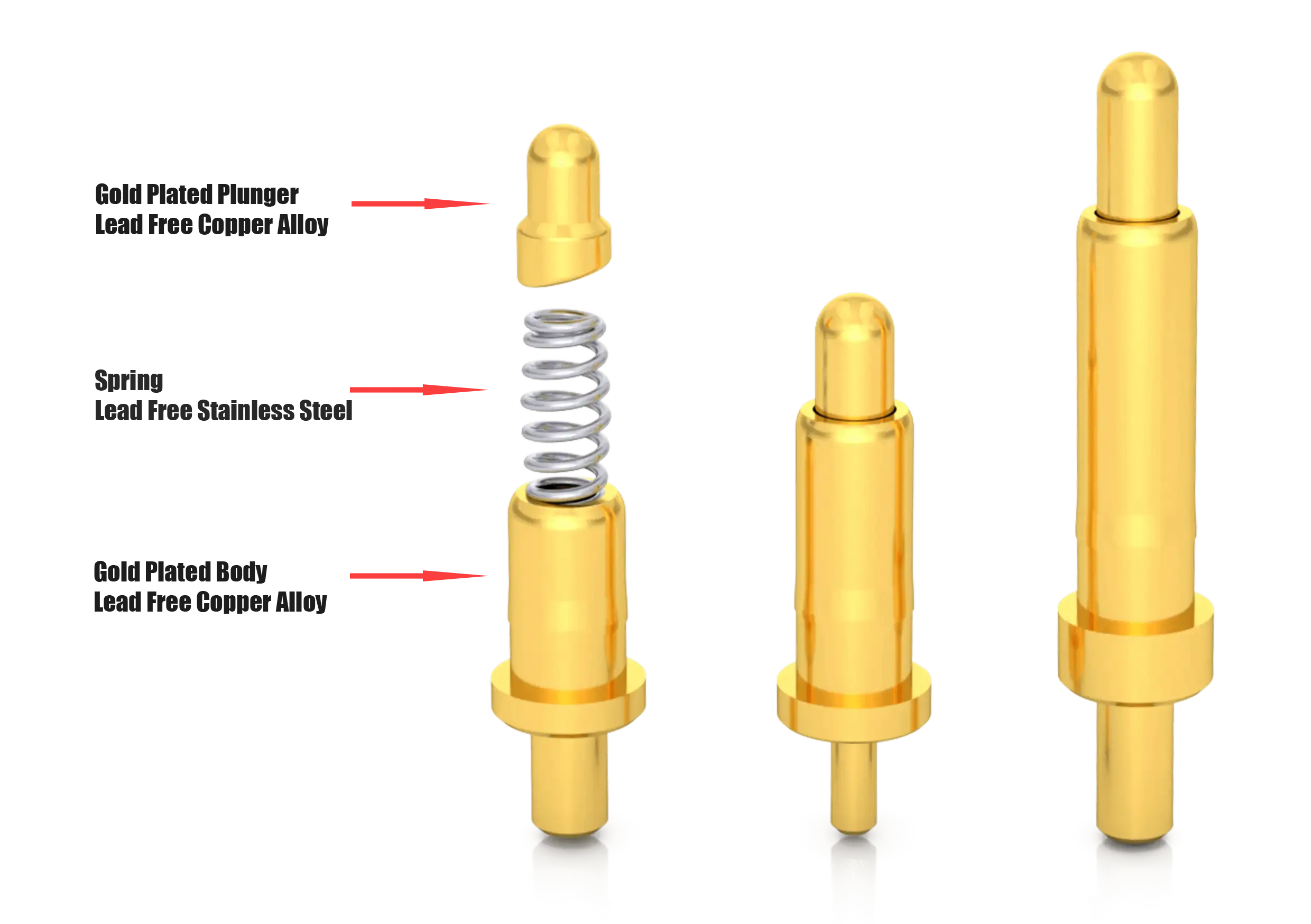

Right angle pogopin material & Parts

A right angle pogo pin is a spring loaded contact designed to transmit electrical signals or power when space or layout constraints require a 90 degree connection. In this design, the barrel or tail is bent or formed at a right angle, allowing horizontal mounting while maintaining vertical contact at the tip. It is commonly used in test fixtures, PCB connections, and compact electronic assemblies, and the right angle structure improves flexibility and routing efficiency in dense electronic layouts.

The main materials and parts include the plunger, barrel, and spring. The plunger is typically made of brass or beryllium copper for good conductivity and mechanical strength, and is often plated with gold over nickel to reduce contact resistance and improve corrosion resistance. The barrel houses the internal components and provides structural support; it is usually manufactured from brass or phosphor bronze with similar nickel gold plating. The spring, located inside the barrel, is generally made of stainless steel or music wire, providing stable and repeatable contact force over many cycles.

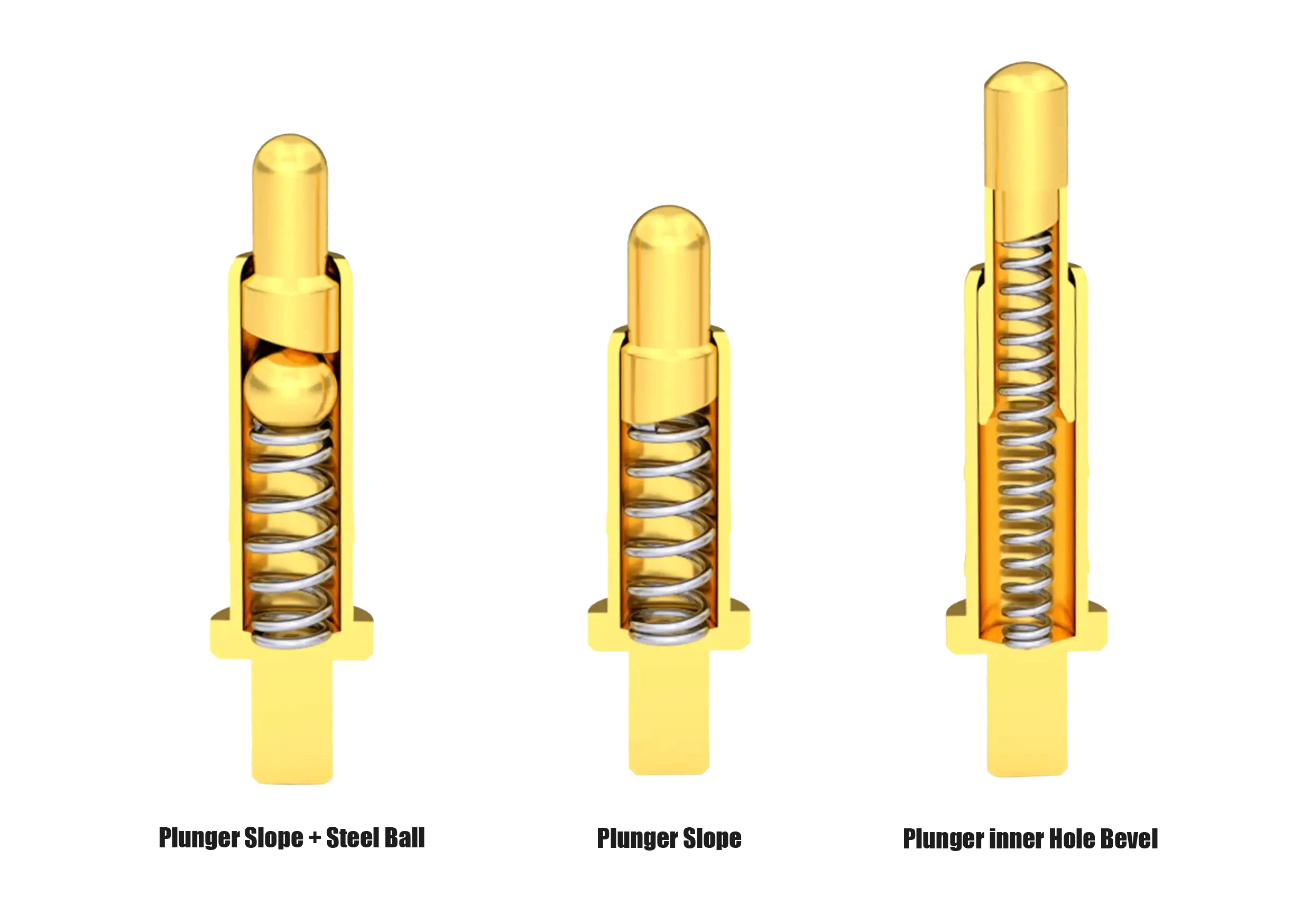

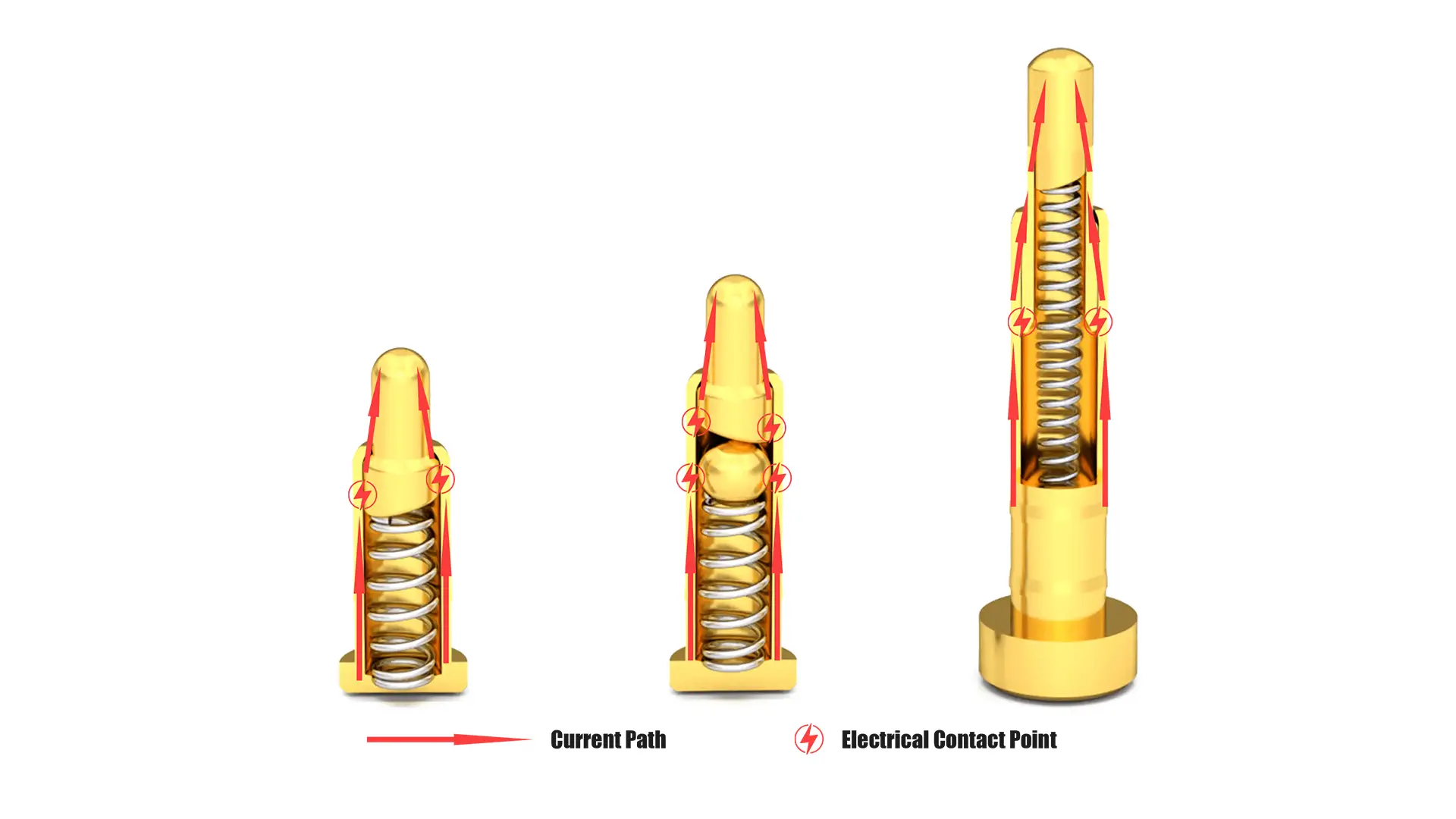

Right angle pogopin internal structures

Right angle pogo pins can accommodate several types of internal structures to convert horizontal motion into reliable vertical spring compression. Common options include a lever or rocker mechanism, where a pivoting arm transfers force at a right angle. Another is a cam or inclined plane structure, which redirects horizontal movement into spring compression via angled surfaces. A dual plunger design uses two interconnected plungers to transmit force perpendicularly. Additionally, some pins use flexure based springs or coil springs with intermediate transfer pieces for compact or low profile applications. Selection depends on stroke requirements, contact force stability, durability, and electrical performance in the target application.

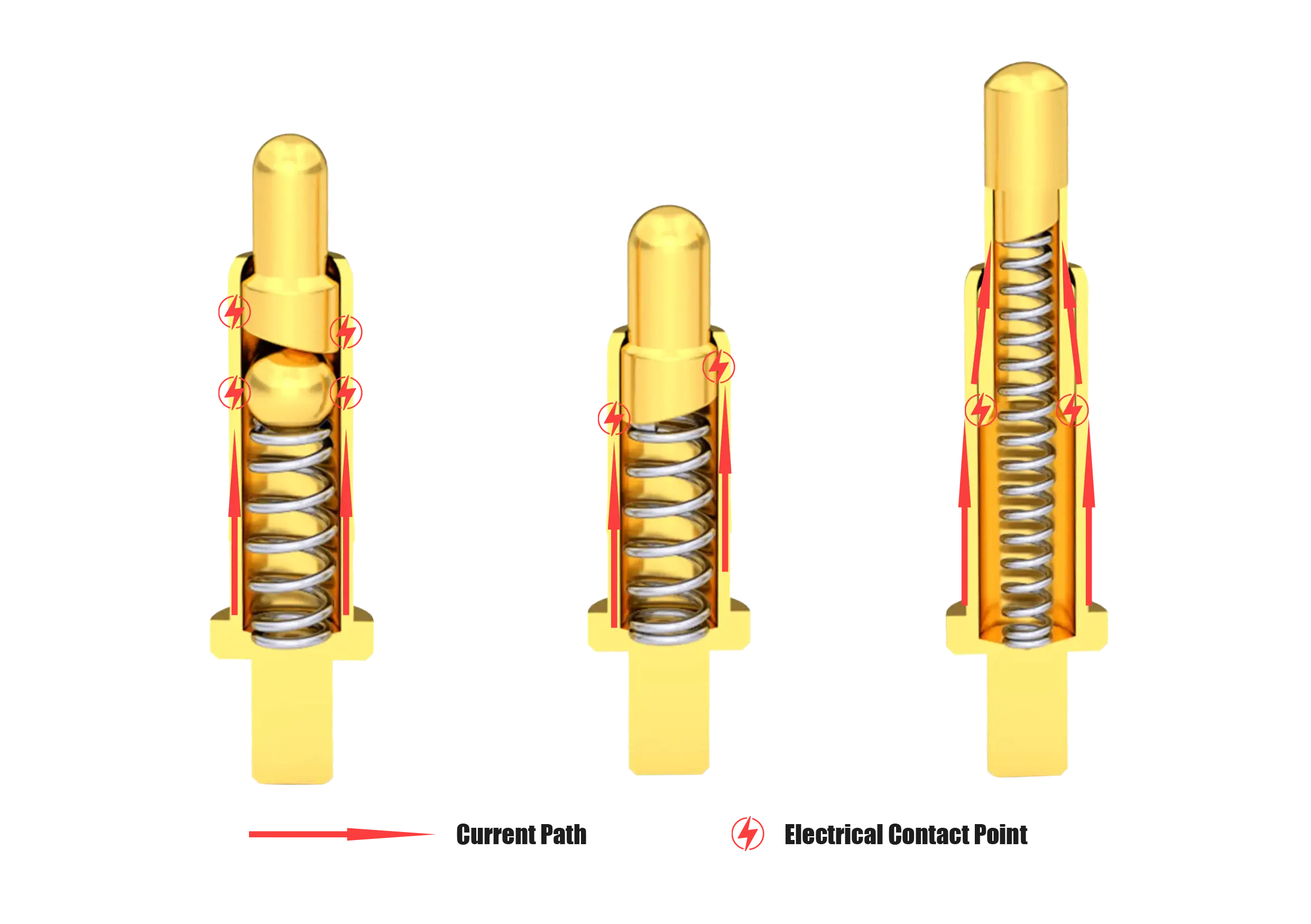

How Right Angle Pogo Pins Work

Right angle pogo pins provide reliable electrical connections by combining an internal spring, beveled plunger, and barrel in a compact 90 degree configuration. When the pin is pressed against a horizontal or edge pad, the spring compresses, generating a lateral force. The bevel structure converts this lateral force into consistent contact force along the plunger, pressing the gold plated tip firmly against the inner wall of the barrel. This ensures extremely low and stable contact resistance, even under vibration, slight misalignment, or repeated insertions. The right angle orientation allows connections in tight spaces where vertical clearance is limited, such as edge mounted PCBs or docking interfaces. The spring mechanism automatically returns the plunger when released, maintaining durability, repeatability, and reliable performance in modular assemblies and compact electronic designs.

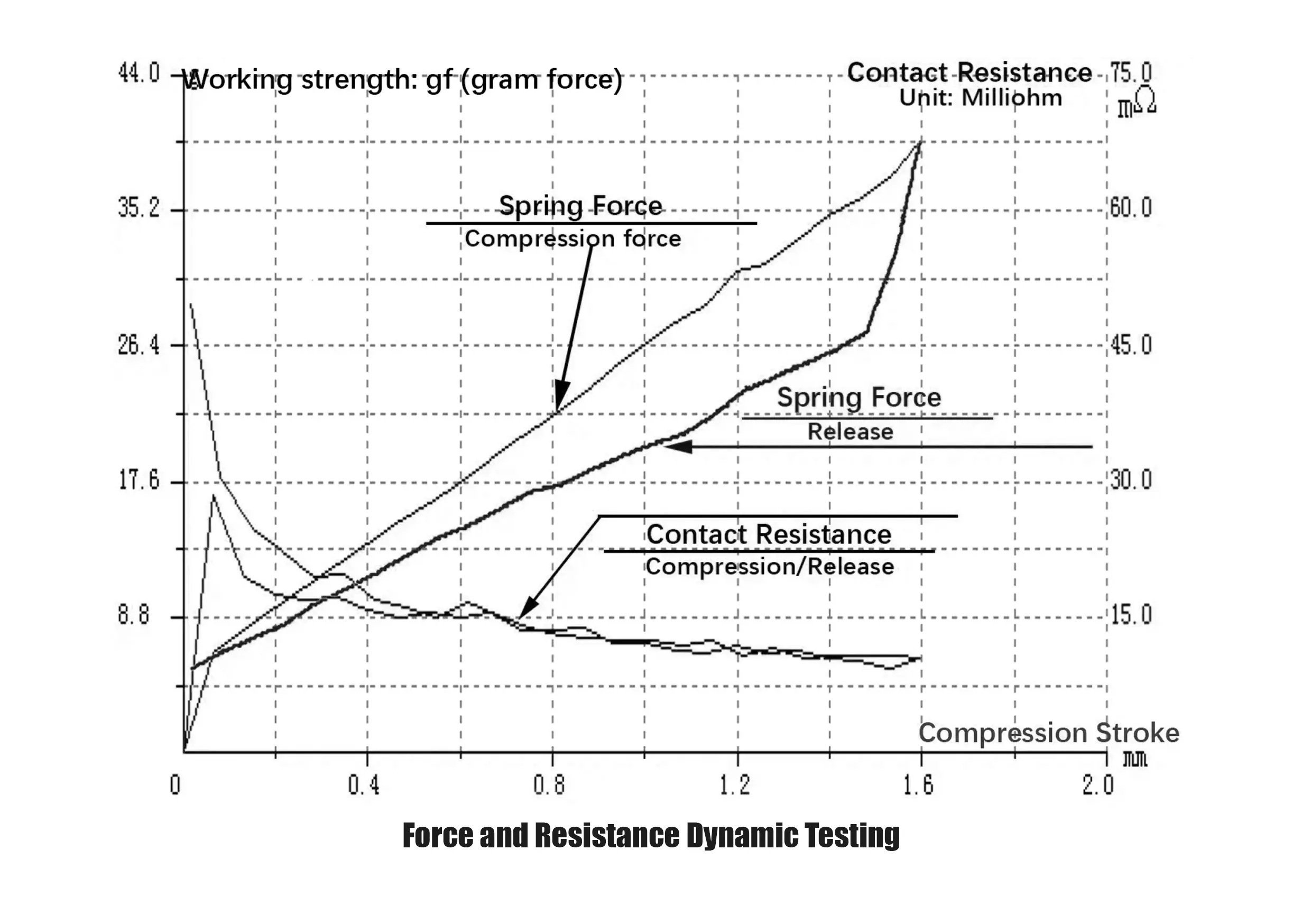

Dip Pogo Pin Contact Resistance

This chart illustrates that during the full compression and release stroke of the dip pogo pin, the spring force increases smoothly while the contact resistance remains extremely low and stable. This demonstrates a well-engineered internal structure, precise machining tolerances, and high-quality vacuum blind-hole plating that together ensure reliable electrical connectivity and long-term performance stability.

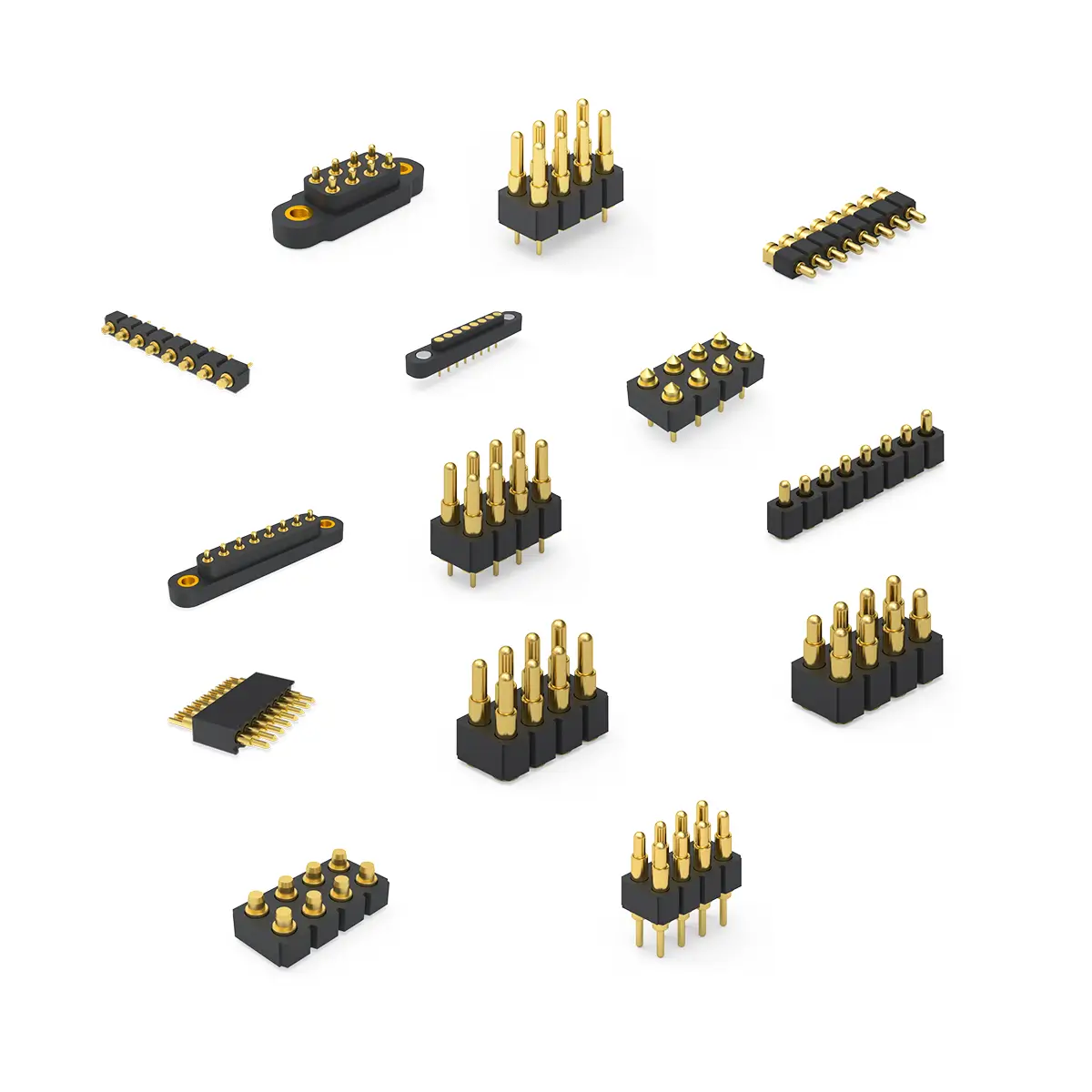

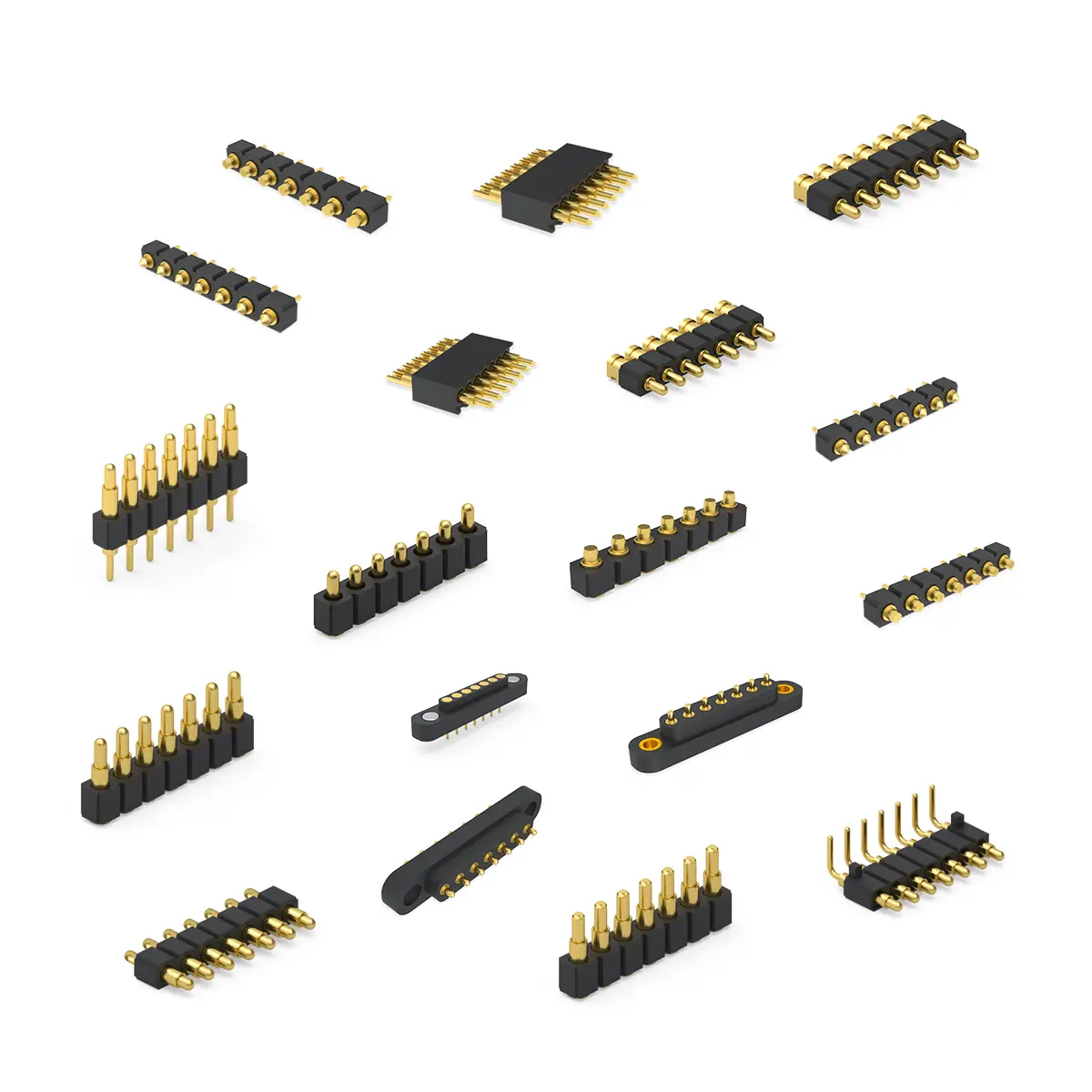

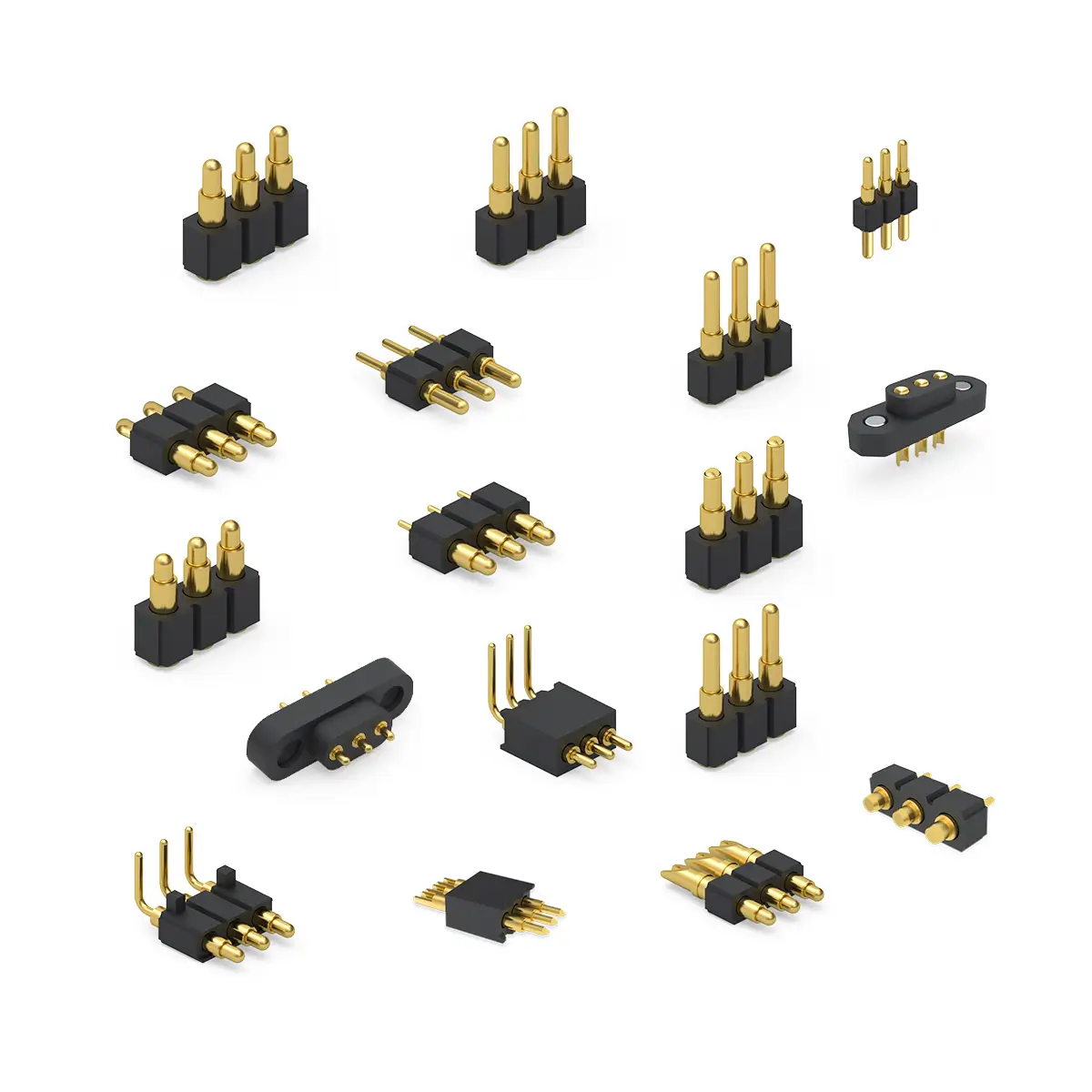

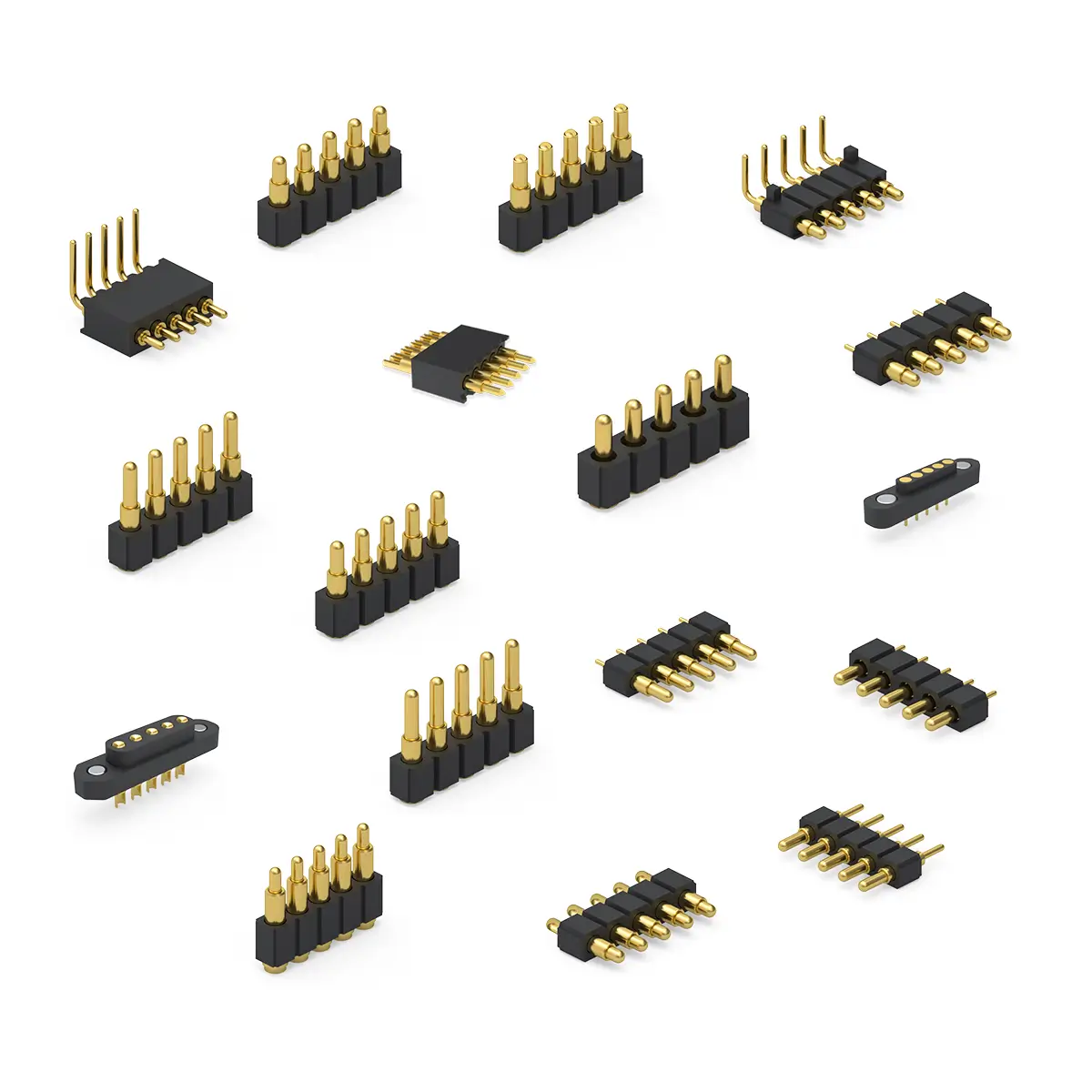

Types of Spring Loaded Right Angle Pin

Selection Guide of Right Angle Pogo Pin

Select right angle pogo pins based on travel length, spring force, contact material, and plating to achieve optimal performance, reliability, and durability.

Fully customizable to meet any electrical, mechanical, or environmental requirements.

| SN | Product Image | Full Stroke (mm) | Initial Height (mm) | Working Height (mm) | Catalog Download |

|---|---|---|---|---|---|

| 1 |  |

0.4~0.8 | 1.80~3.00 | 1.40~2.60 | Short-Dip Pogo Pins |

| 2 |  |

1.00 | 3.15~6.30 | 1.50~5.60 | 1.00-Dip Pogo Pins |

| 3 |  |

1.50 | 4.50~10.00 | 3.20~9.00 | 1.50-Dip Pogo Pins |

| 4 |  |

2.00 | 5.80~16.00 | 4.00~15.00 | 2.00-Dip Pogo Pins |

| 5 |  |

2.50 | 7.10~16.00 | 4.80~15.00 | 2.50-Dip Pogo Pins |

| 6 |  |

3.00 | 8.40~20.00 | 5.60~19.00 | 3.00-Dip Pogo Pins |

| 7 |  |

3.50~5.00 | 9.70~20.00 | 6.40~19.00 | 5.00-Dip Pogo Pins |

Right Angle Spring Loaded Pin Performance

Right Angle Pogo Pin Technical Parameters

Alizn custom pogo pins are carefully crafted using only the finest materials.

Our production team offers superior craftsmanship with over 10 years of experience working with custom right angle pogo pins / right angle pogo pin connectors.

| Items | Details |

|---|---|

| Material | Plunger: Lead-Free Copper Alloy |

| Body: Lead-Free Copper Alloy | |

| Spring: Stainless Steel | |

| Solid Pin: Lead-Free Copper Alloy | |

| Main Technical Parameters | Standard state: |

| Operating temperature: -40~+120°C (Standard) | |

| Operating humidity: 20-85% RH | |

| Storage temperature: -10~+50°C | |

| Storage humidity: 20-85% RH | |

| Rating voltage: 36V AC/DC (Standard) | |

| Rating current: 2A/Pin Continuous (Standard) | |

| Contact resistance: 30 mΩ Max. (Standard) | |

| Withstanding voltage: 250V AC, 1 Minute | |

| Insulation resistance: 500 MΩ Min. | |

| Durability: 10,000 Cycles (Standard) | |

| Working Spring Force: 40~120 gf (Standard) | |

| Electroplating | Plunger: Ni Plating 1.4μm, Gold Plating 0.30μm |

| Body: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| Solid Pin: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| Contact Type | Vertical Contact Type |

| Installation Method | SMT automatic placement machine + Reflow soldering |

| Plugin machine + Wave soldering | |

| Environmental Protection Standard | Comply with EU RoHS and Alizn standards |

Upload Your CAD File

To begin, provide your contact details and upload the CAD file or detailed product requirements of your design. This allows us to create a detailed 3D model of the part or prototype you're looking to produce.

Receive a Quote & Design Review

Within 12 hours, we’ll send you a detailed quote along with Design for Manufacturability (DFM) feedback. This ensures the feasibility of your project and gives you a clear idea of the costs involved.

Confirm Your Order & Begin Production

Once you approve the quote and design, we’ll proceed with the production of your custom right angle pogo pins.

Shipping & Delivery

Your project enters our manufacturing queue the morning after we receive your approval. On average, custom orders ship within 10-15 business days. In stock products and samples ship within 48 hours.

Just 4 Steps

Custom Right Angle Pogo Pin Quotation Process

From detailed consultation to final delivery, we make custom pogo pin orders simple and easy. We pride ourselves on providing exceptional customer service by anticipating your needs, offering customized solutions and on time delivery.

Right Angle Spring Loaded Pins Electroplating

Right Angle Pogo Pin Surface Treatment

Various surface treatment methods to meet your needs

Electroplated Gold - Golden Yellow

Electroplated Nickel - Silver White

Before Electroplating - Brass Color

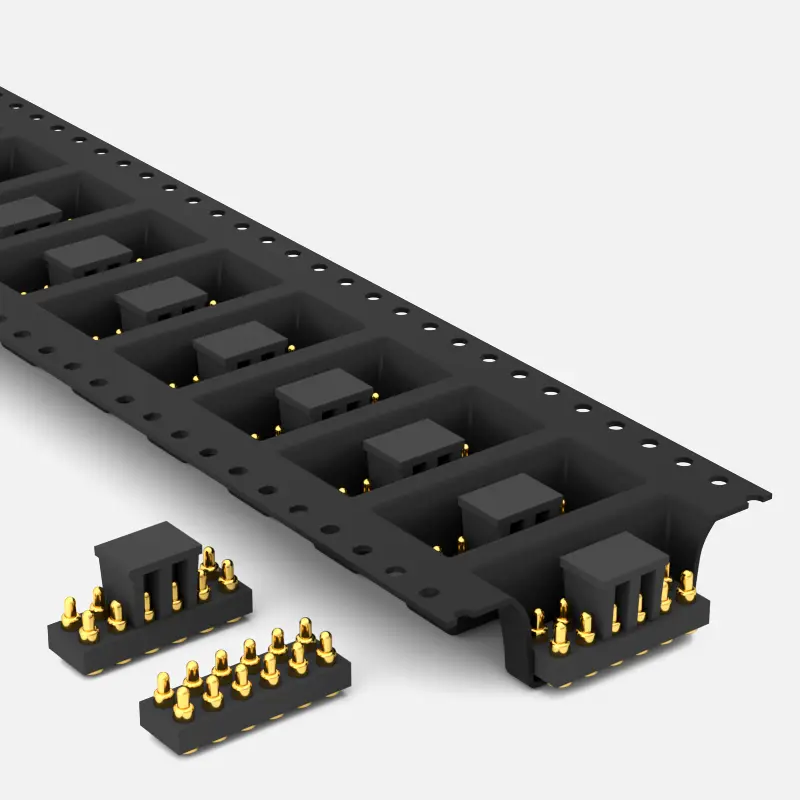

Packaging Options for Right Angle Pogopin

Pogo Pin Packaging Method

Enabling you to move seamlessly from receiving to production without compromise.

Pogo Pins Vacuum Carrier Tape Packaging

Pogo Pin Connector Vacuum Carrier Tape Packaging

Right Angle Contact Pin Customization Process

From Design to Quality Control

Every Step Tailored to Perfection

Alizn right angle pogo pin customization process ensures precision, quality, and efficiency at every stage. From innovative design and advanced production to rigorous quality control, we transform your ideas into high performance solutions. Serving diverse industries, we specialize in creating prototypes and full scale production, turning your vision into reality with unmatched expertise and attention to detail.

- RX Feugiat 2000

- 4-5 months

- $ 8,400

Professional Equipment For Right Angle Springloaded Pin

The Equipment Behind Custom Pogo Pins

Our professional equipment provides complete solutions for pogo pin customization, ensuring high precision, efficiency, and cost effectiveness.

From design to production, we meet strict quality standards, addressing complex shapes and performance needs.

automatic lathe

High speed auto feeding turning

milling machine

Complex precision machining

stamping press

High accuracy & rigidity

spring coiling machine

Free height & wire diameter precision

electroplating machine

Uniform, clean

coordinate measuring machine

Dimensional & tolerance verification

Alizn Pogo Pin

Related Pogo Pin

From initial prototypes to large scale production, we ensure top quality results and help you achieve your manufacturing goals.

Pogo Pin Professional Guide

Pogo Pin Knowledge

Alizn explores with you every factor that influences your choice design, functionality, durability, price factors, process, customization options

Right Angle Pogo Pin FAQ

Alizn high performance pogo pins, ideal for functional tests or end use applications. Explore our FAQs to discover more about our pogo pin solutions and related technical support.

We need drawings or key specs: size, stroke, force, current, plating, and usage.

Standard parts: 3–7 days. Custom parts: 2–4 weeks depending on complexity.

Yes, sample testing can be provided before mass production.

Yes, we can design sealed / IP67–IP68 waterproof structures.

Yes, we support full customization based on size, force, plating, and structure.